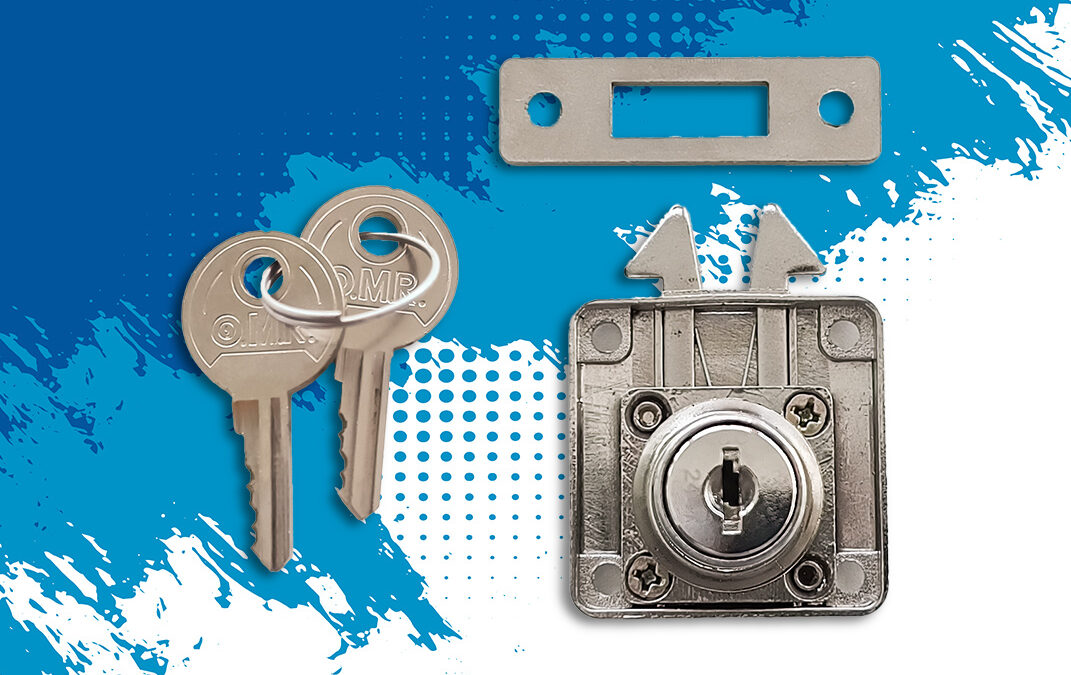

On-site processing of Zamak: from raw material to finished part

The history of OMR Serrature is characterised by a strong attention to quality and innovation. Already in the first years of activity, the company distinguished itself for the introduction of new technologies and materials, which made it possible to produce ever more resistant, long-lasting and safe locks.

Today, OMR Serrature continues to be an example of real Made in Italy. As a matter f fact, the society controls the whole processing cycle, from the project to the delivery of the final product, and guarantees quality and precision at every phase of the production process. Thanks to an optimized and autonomous management of the processes, the company is able to offer tailor-made locks, customized according to the customer’s needs.

In the video below, you can take a look at the various departments of the establishment in Borgaro Torinese, in particular among the machines involved in the processing of zamak, an alloy of zinc, aluminium, magnesium and copper. Thanks to its strength and ductility, zamak is widely used in the manufacturing industry for the production of mechanical and precision parts, such as clock parts, door and window handles, and obviously the components of OMR locks. The zamak alloy has a vast range of applications, it is self-lubricating and therefore perfect for mechanical sliding, it is economical and it allows for the molding of complex, high-performance products at competitive prices.

The production process of the zamak pieces begins with the foundry. The raw material is melted in a crucible and brought to a liquid state, then the second phase, the injection, takes place, when the molten zamak alloy is injected into a pressure mold. This creates parts with a precise and repeatable shape in large quantities. Then the newly made piece falls into a container together with the waste from which it is manually separated before the last finishing phase, when the parts are levigated to remove any imperfection and to make the surface more homogeneous. This phase can be carried out with the help of specialized machines and equipment. Once the finishing is completed, the pieces are ready to be assembled or for any other esthetic-functional treatments.

Zamak processing is just one of the many internal processes optimized and managed by OMR. Thanks to its production, technical and engineering autonomy, OMR is able to adapt to the specific needs of customers and to produce custom-made locks, whether they are for new uses or a replacement. The production of OMR locks is highly optimized, which means short lead times and fast shipping. The company constantly invests in technological innovation to improve production processes and ensure a high level of product quality, in fact OMR is UNI ENI ISO 9001 certified: all processes comply with international quality standards.

In a world where security is increasingly important, choosing OMR Locks as your partner means having an extra guarantee on quality, accessing high levels of customization, enjoying fast turnaround times and an unparalleled focus on customer satisfaction. If you are looking for high quality locks, entirely made in Italy, the best option is OMR Serrature. Choose true made in Italy, choose OMR.

0 Comments