If mounted outside, locks suffer from humidity, temperature swings, splashing water and dirt that might damage the external body of the lock, but that can also pervade the internal mechanism. This naturally impairs the lock’s performance and durability by causing resistance to rotation resulting in collateral damage such as breaking the key inside the cylinder. Think about locks mounted on heavy vehicles (for instance, on toolboxes or isothermal boxes), on motorcycle cases, bike racks, ski racks and roof boxes, or even about locks used in the world of gate automation or on carpentry products exposed to severe weather.

In these cases, expedients such as a stainless steel cap on the cylinder head, a dust flap, or protective surface treatments such as zaponating may not be sufficient to ensure the lock’s function and durability.

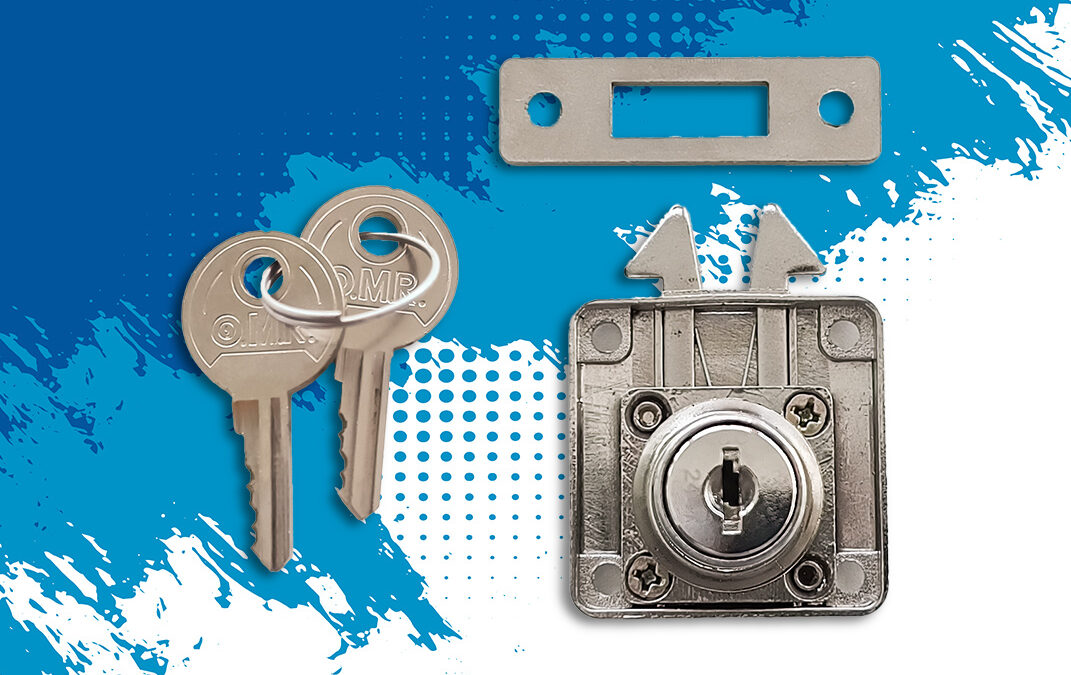

Lock cover cap: universal, and watertight

For this reason OMR has producted a new protective waterproof cap in thermoplastic resin for all kinds of locks. . The lock housing features the classic double-D shape (with flat sides on the sides) to accommodate all types of cam locks. The cap, connected to the base by a sturdy jumper designed to withstand numerous opening and closing cycles, ensures watertightness and resistance to stress, preventing unwanted opening.

0 Comments