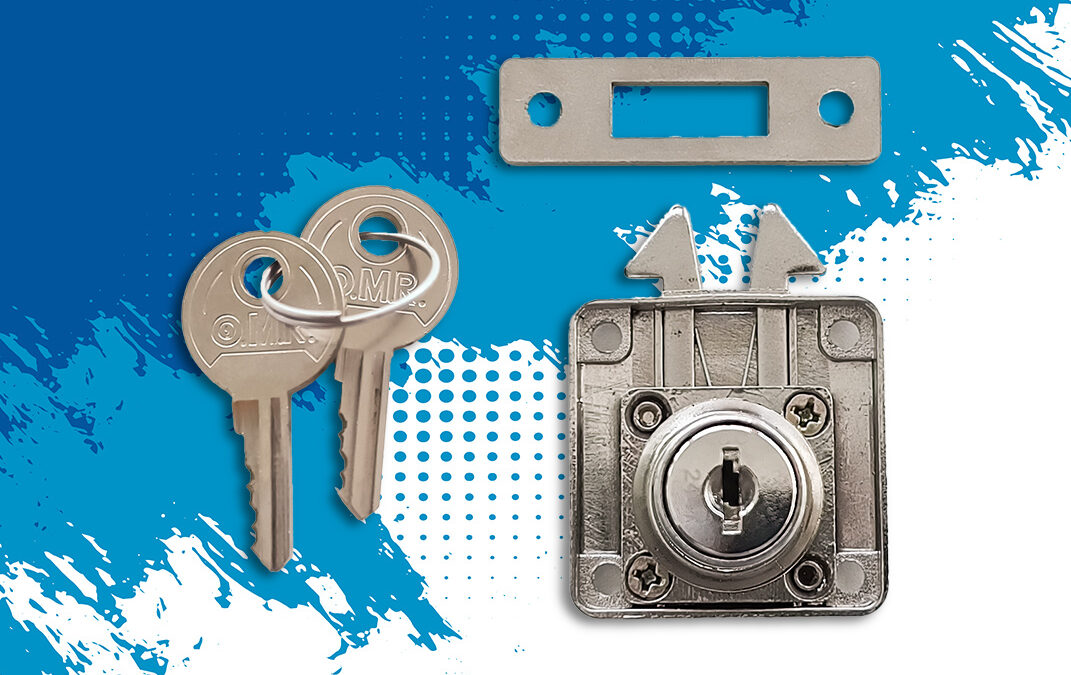

OMR technopolymer locks represent a breakthrough in innovation and security. This advanced material, known as “engineering plastic,” offers a superior alternative to traditional die-cast metal locks. OMR’s line of technopolymer locks maintains the same level of security and stability as their metal counterparts, but additionally offers a number of innovative features at competitive costs.

What is technopolymer and why it makes sense to employ it in lock manufacturing

Engineering polymer, or “engineering plastic,” is an advanced material with distinctive technical characteristics that make it particularly suitable for a wide range of applications, especially in contexts where traditional materials (such as metals and alloys) may not be an ideal choice. Engineering polymer combines strength, light weight, versatility and great processability, making it an excellent option for replacing metals in many applications, from industrial production to everyday use. Let’s take a look together at the strengths of this amazing plastic material:

- Physical and mechanical properties: Technopolymer is distinguished by its stiffness, toughness, and stability at elevated temperatures. These properties make it an excellent structural material, capable of replacing metals and in many cases improving design performance. This special plastic material really fears nothing: weather, extreme cold and heat, salt, dust, mud, technopolymer is really a super material. In locks, it is used for the supporting structure (bushing and barrels) to provide unparalleled strength to the outside of the lock.

- Lightness, strength and durability: technopolymer is known for its lightness and great resistance to aging; in fact, it maintains its physical and mechanical characteristics over time without significant mutation. Strength also extends to static and dynamic loads, as in the case of locks, ensuring that the material maintains its integrity even when subjected to mechanical and chemical stresses.

- Versatility in design: thanks to its molecular structure, technopolymer offers high processability that results in virtually endless design possibilities. The production of OMR’s technopolymer locks is therefore flexible, offering a high level of product customization according to customers’ needs. Technopolymer can be produced in different colors, which do not peel or flake off because they are in the paste of the material itself.

Applications of technopolymer locks

OMR technopolymer locks find application in a wide range of industries due to their exceptional strength and durability properties.

- Naval and port sector. Technopolymer locks are ideal on ships and in port facilities. These locks have to cope with harsh conditions such as cold, sweltering heat, rain, wind, salt water, and corrosion, as well as having to withstand stress and mechanical loads. The resistance of engineering polymer to these environmental factors makes it a preferable material over stainless steel.

- Resistance to dirt and dust. The technopolymer is highly resistant to dirt and dust, ideal for permanent outdoor installations and an excellent choice for iron box locks on trucks and other equipment that must provide weather resistance and minimal maintenance while remaining exposed to the elements.

- Industrial applications. Because of its versatility, engineering polymer is used in a variety of industries, including electrical, electromechanical, construction and transportation. Its dimensional stability, resistance to dynamic loads and aging make it suitable for security and access-control products .

- Use in specific environments. Technopolymer locks are perfectly suited for use in specialized environments such as aircraft, plumbing and valve industries, and even for locks in furniture and equipment for radiology rooms, and hospitals in general. Their nontoxic nature also makes them suitable for use in the food and pharmaceutical industries. In addition, their ability to aesthetically integrate with various colorations makes them ideal for enhancing the aesthetic appearance of any artifact .

- Home and industrial security. Whether for beach lockers or outdoor chest locks, water meter doors, gas doors, and outdoor mailboxes, technopolymer locks offer a durable security solution. Their resistance to high temperatures and direct sunlight also makes them perfect for balcony cabinets, ensuring secure and reliable locking even after years of use.

Technopolymer locks are extremely versatile, lightweight, and robust, ideal for a wide range of applications where resistance to environmental, mechanical, and chemical stresses is critical. Contact our customer service department to submit your engineering polymer project to OMR’s team of experts.

0 Comments